The Siempelkamp Group is a technology supplier operating internationally and consisting of three business units: the machine and plant engineering, the foundry technology, and the engineering and service business unit. Siempelkamp machine and plant engineering is a systems supplier of press lines and complete plants for the wood-based panel industry, the metal forming industry as well as the composite and rubber industry. The Siempelkamp foundry is the world’s largest hand-molding foundry producing castings with a weight of up to 320 t (353 US tons). Siempelkamp engineering and service is a component supplier and service provider for nuclear facilities.

- Foundation: Over 130 years of experience in machine and plant engineering and numerous successfully completed projects worldwide.

- The goal: The optimum in solutions for each customer requirement.

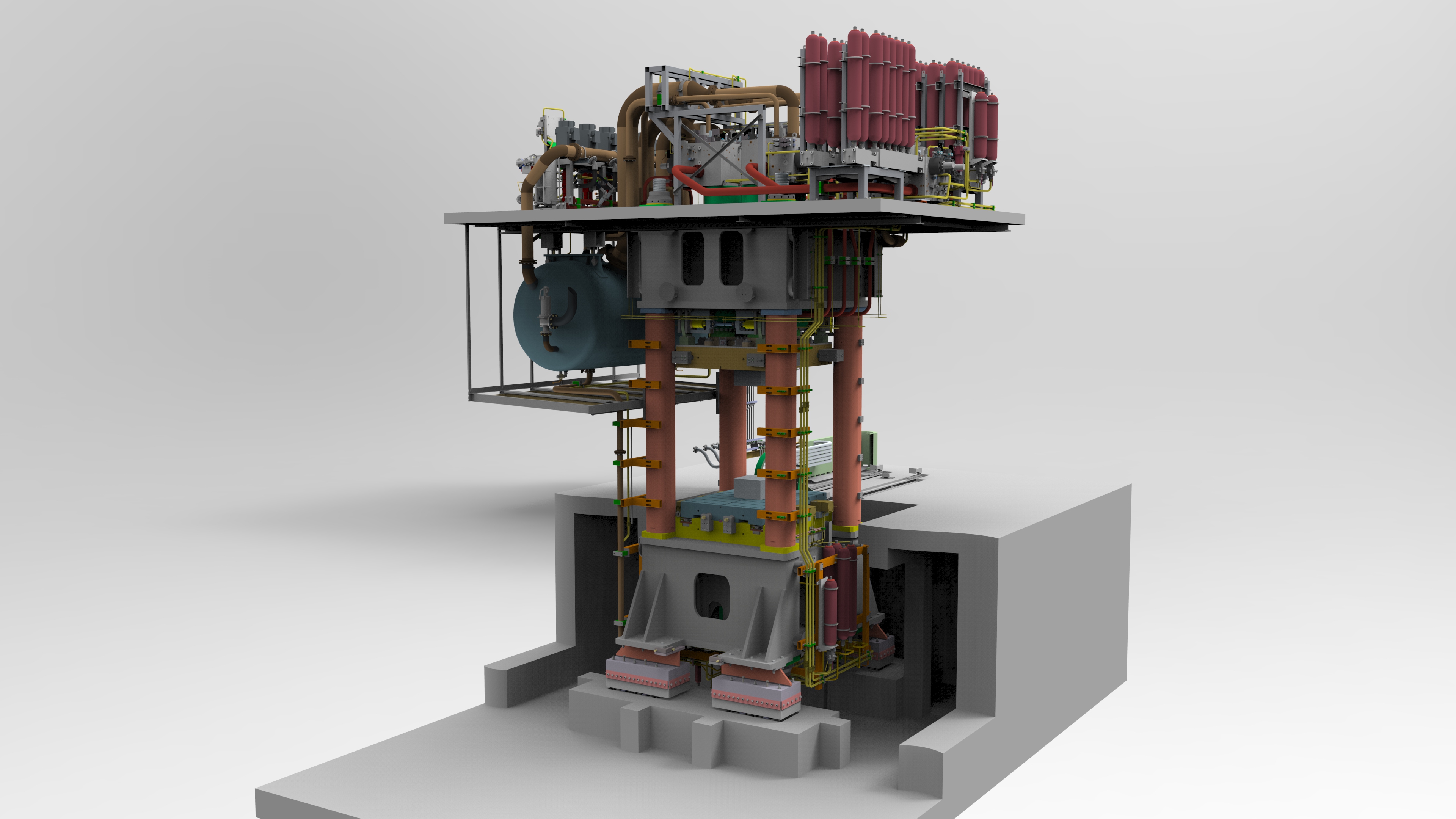

Siempelkamp Maschinen- und Anlagenbau develops press systems and complete plants for the wood-based materials, rubber, and metal forming industries.

Plant operators are provided with a full service package: We are in control of the respective processes and develop customer-specific machine concepts as well as complete system solutions. Development, calculation, design, manufacture as well as assembly and startup are from a single source.

Pressure and counterpressure

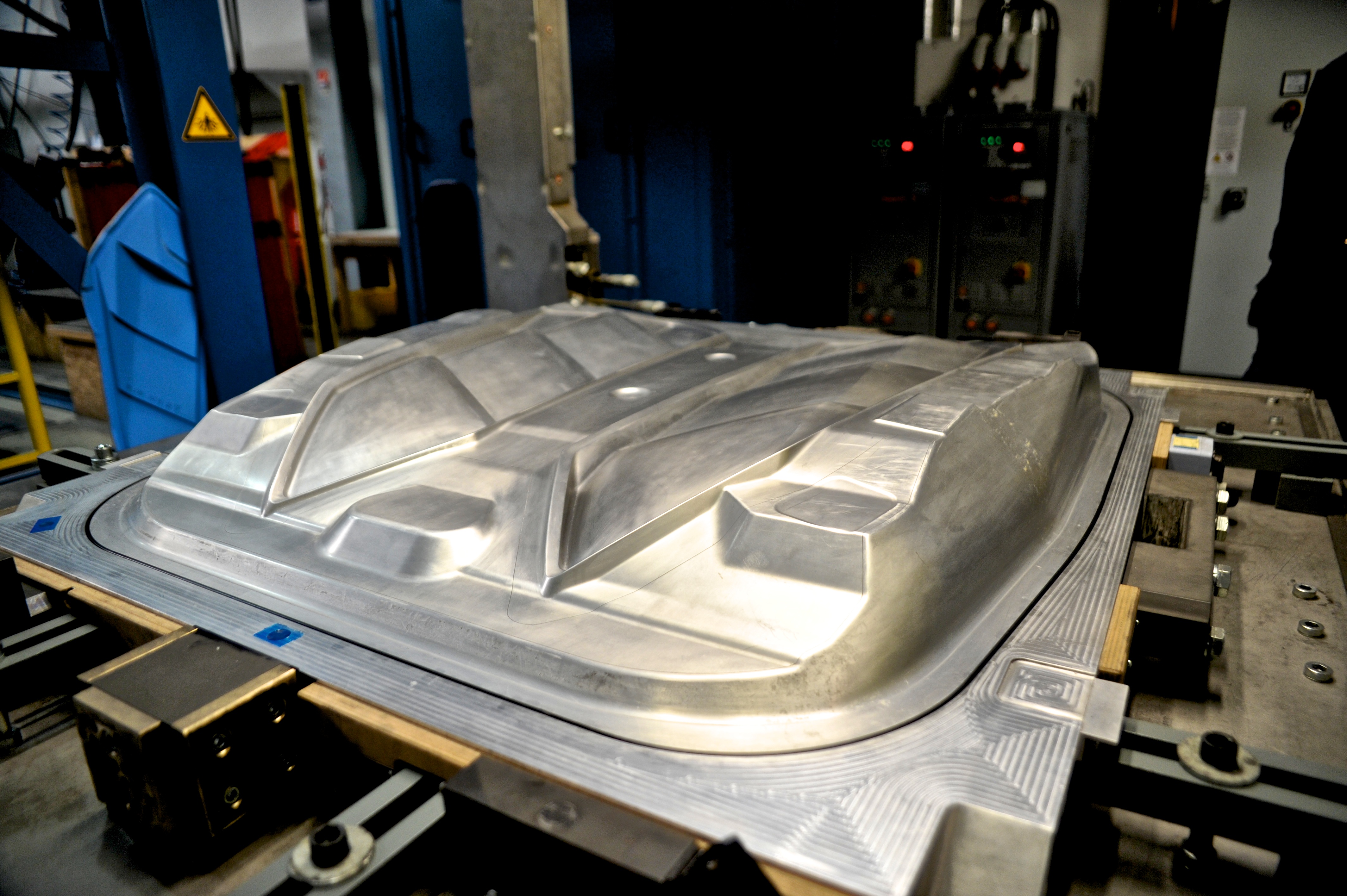

In the RTM process, the press has to manage other tasks in comparison with the sheet molding process: First the upper tool has to drive exactly to a defined gap position. When the resin is injected, it is important to maintain the gap width constant and adjust it as needed.

The backlash-free suspension of the ram plate ensures that the thickness profile of the components is precisely maintained, even when high pressure is built up during injection.

Well-directed flow of resin

The individual closed loop control of the four cylinders has great advantages, especially for surface and structural components with complex geometries: the upper tool can be tilted in a targeted manner. Thus, the resin flows in a closed front, creating a smooth surface.

The control is so flexible that the upper tool can be tilted up and closed in an “inclined position”. Even during coating with the IMC process, where the gap is opened by a few tenths of a millimeter, the clearance-free control of the gap width is proven.

Complete production plants

The system solutions from Siempelkamp covers all process steps from unrolling the fabrics through the processes up to the finished, stored parts:

- Cutting fabrics to size

- Preform production with draping, binding, preforming

- Loading

- Pressing, injecting

- Unloading, inspection

- Deburring, edge trimming

- Joining

Siempelkamp supplies integrated shuttle systems for material feeding and tool change:

- Sliding table for manual tool change

- One-way shuttle for the lower tool

- Two-sided shuttle for the parallel handling during pressing

- Fully automatic tool changing systems

Find out more information about press systems and complete production plants.

Carsten Daub

Sales Director Composites Division

carsten.daub@siempelkamp.com

+49 2151 92 43 53

Siempelkamp Maschinen- und Anlagenbau GmbH

Siempelkampstraße 75

47803 Krefeld

Germany